Address:Room 906, building 6, SIIC Center, No.195 Hong Kong East Road, Laoshan District, Qingdao city, Shandong Province, China

E-mail:info@deltachem.net

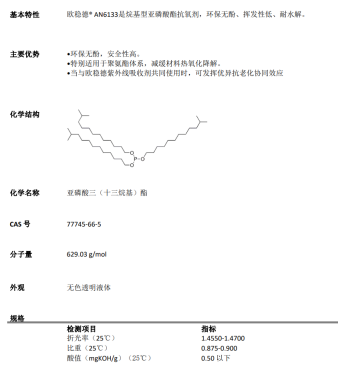

Product characteristics

Omnistab®Antioxidant AN6133 exhibits excellent performance in various materials, especially in the field of polyurethane flexible foams, due to its unique molecular structure. Its structure is composed of three long-chain tridecyl groups bonded to a phosphite linkage, which design endows it with antioxidant properties, hydrolysis resistance, and high-temperature stability, specifically manifested as follows:

lEfficient antioxidant capability: By capturing free radicals and decomposing peroxides, it effectively delays the oxidative degradation of materials, thereby extending their service life.

lExcellent thermal stability: It remains active under high-temperature processing or operating conditions (such as above 180°C), preventing yellowing of polymers or degradation of mechanical properties.

lCompatibility of long-chain alkyl groups: The hydrophobic long-chain structure of tridecyl groups makes it highly compatible with oily systems (such as lubricating oils and plasticized PVC), avoiding the issue of precipitation.

lLow toxicity and environmentally friendly: Phenol-free and compliant with regulations such as REACH, suitable for end products with strict environmental requirements.

Application Areas

lProcessing of polymer materials

Polyurethane (PU): With advantages of low volatility, good heat resistance, and hydrolysis resistance, it can effectively improve the thermal stability of polyurethane foam and resist smoking (NOx) yellowing.

Polyolefins (PP/PE): Used as a secondary antioxidant in synergy with primary antioxidants (such as phenols), it enhances resistance to thermal oxidative aging and reduces melt fracture.

PVC products: In flexible PVC (such as cables, flooring), it inhibits the migration of plasticizers and discoloration caused by thermal decomposition, maintaining product flexibility.

Engineering plastics (ABS, PC, etc.): During high-temperature injection molding or extrusion processes, it reduces material degradation, ensuring the appearance and strength of the products.

lLubricant and fuel additives

Industrial gear oils/hydraulic oils: Delays oil oxidation and rancidity, reduces sludge formation, and extends oil change intervals.

Bio-based lubricants: Strong compatibility with natural ester base oils, supporting the development of green lubrication solutions.

lCoatings and adhesives

Acrylic resin systems: Prevents yellowing of coatings during baking or prolonged outdoor exposure, enhancing weather resistance.

Polyurethane adhesives: Inhibits oxidative side reactions during high-temperature curing, ensuring stable bonding strength.

Why choose "Omnistab®Antioxidant AN6133"?

lA new generation of phenol-free phosphite antioxidant

Free from free phenol substances such as phenol, nonylphenol, and bisphenol A. It has the advantages of low volatility, good heat resistance, and hydrolysis resistance, effectively improving the thermal stability of polyurethane foam and its resistance to smoking (NOx) yellowing, while slowing down the thermal oxidative degradation of materials.

lLong-lasting protection with outstanding cost-effectiveness

Compared to traditional phosphites, it provides more lasting antioxidant effects, reduces the amount of additive required, and lowers overall costs. When used in conjunction with Omnistab® UV absorbers, it exhibits excellent synergistic anti-aging effects.

lWide process adaptability

Omnistab® Antioxidant AN6133 can also serve as an efficient secondary stabilizer and chelating agent in soft/rigid PVC materials, effectively enhancing their processing thermal stability and light stability, while maintaining color stability and transparency of the products. It is a highly effective antioxidant for rubber materials such as ABS, SBS, SIS, and SEBS.

lGreen and safe, aligning with trends

Environmentally friendly and phenol-free, with high safety. Free from heavy metal components, its low volatility characteristics reduce VOCs emissions in the production environment, meeting the needs of sustainable development.

Product Technical Parameters

In addition, our company can recommend a variety of specialized additive products based on customer needs, and provide corresponding technical guidance and recommendations for product compounding and usage, in order to offer customers more efficient and high-quality product services.

If you need further product samples or technical support, please feel free to contact us! Deltachem Special Chemical Groups is fully committed to serving you!