Address:Room 906, building 6, SIIC Center, No.195 Hong Kong East Road, Laoshan District, Qingdao city, Shandong Province, China

E-mail:info@deltachem.net

Nylon material, also known as polyamide, is one of the major engineering plastics. With the innovation development of polymerization technology, its application fields have been continuously expanded. Nylon serves as a key material for load-bearing components and functional parts in industries such as automobiles, electrical components, aerospace, and instrument manufacturing. It also has extensive applications in the field of high-strength fibers. However, nylon also has some drawbacks. For instance, it is sensitive to sunlight, and prolonged exposure to sunlight can cause the material to yellow and lose strength. To meet the diverse demands of the market, we can enhance the performance of nylon through modification to ensure their suitability for various application scenarios.

Main applications of nylon:

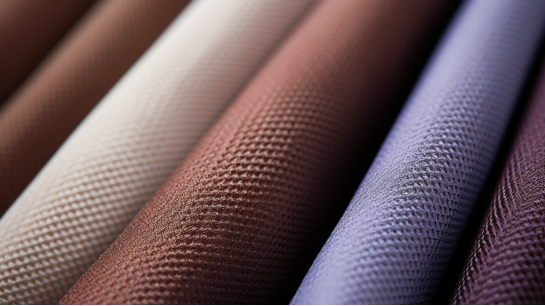

Textile industry

Nylon has a influential history in the textile and apparel industry. With its high strength, abrasion resistance and good elasticity, nylon fibers are ideal for making high-quality suits. From everyday socks and underwear to specialized sports equipment and outdoor apparel, nylon materials have won the market's favor for their superior durability and comfort.

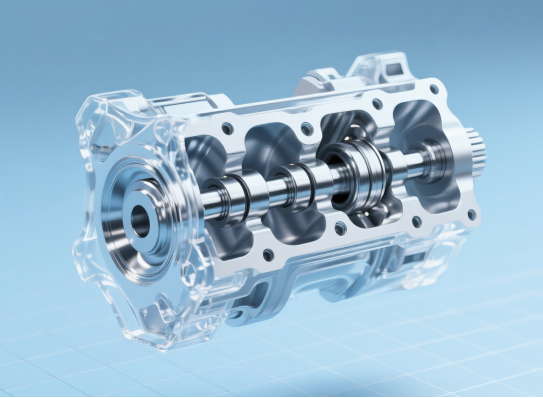

Mechanical Manufacturing

Due to its light weight, high strength, good abrasion resistance and certain self-lubricating properties, nylon is widely used in the manufacture of mechanical parts. Bearings, gears, gaskets, seals and other key components, the use of nylon materials can significantly reduce friction and wear, improve the efficiency and stability of mechanical operation.

Automotive Industry

In automotive manufacturing, nylon is widely used in engine parts, electrical connectors, piping systems, and body components.... Its lightweight properties help reduce overall vehicle weight and improve fuel efficiency.

Electronic and Electrical Equipment

Nylon is widely used in the manufacture of wire and cable insulation, electrical switches, sockets and other components.

Medical Supplies

In the medical field, nylon materials also play an important role. Surgical sutures, artificial blood vessels, infusion tubes and other medical supplies are often made of nylon. Nylon has good biocompatibility and mechanical properties, can be stabilized in the body and play a therapeutic role.

OMNISTAB ® LS5519 is an efficient light stabilizer specially developed for nylon materials. It’s a replacement for Nylostab S-EED, and is a multi-functional stabilizer particularly suitable for nylon.

Key benefits of OMNISTAB® LS5519:

●LS5519 can enhance the stability of nylon melt, thereby improving the processing performance of nylon, reducing the breakage rate of fibers and enhancing product quality.

●It has long-term and stable effects on light, heat and oxidation, and can improve the dispersion of pigments and fillers in nylon.

●Enhance the tinctorial strength and stability of pigments, improve the dyeability of nylon fibers, enhance the dyeing performance. Due to its basic groups and secondary effects, it can enhance the affinity of metal dyes and acid dyes, enabling them to be economically, stably, ecologically compatible and achieve deep dyeing.

●It possesses light stability, antioxidant property and effectively slows down the aging of nylon.

●It has good stability even under high-temperature processing conditions.

Besides LS5519, OMNISTAB UV1577, OMNISTAB UV1164, OMNISTAB AN1098, OMNISTAB AN626 are also widely used in nylon production to improve the long-term weathering resistance and light and heat stability of nylon. Welcome to contact us!